The use of feed barges can significantly improve the efficiency of feeding and rearing fish. However, they can also be a significant investment for operators due to the sheer complexity and variety of equipment that can be on board.

From feed systems with capacities of up to hundreds of tonnes, to huge hoppers and even control rooms, these structures require robust communications, power and resilience in order to run correctly and at maximum efficiency. If not, and a barge fails or sinks, the costs can be in the millions.

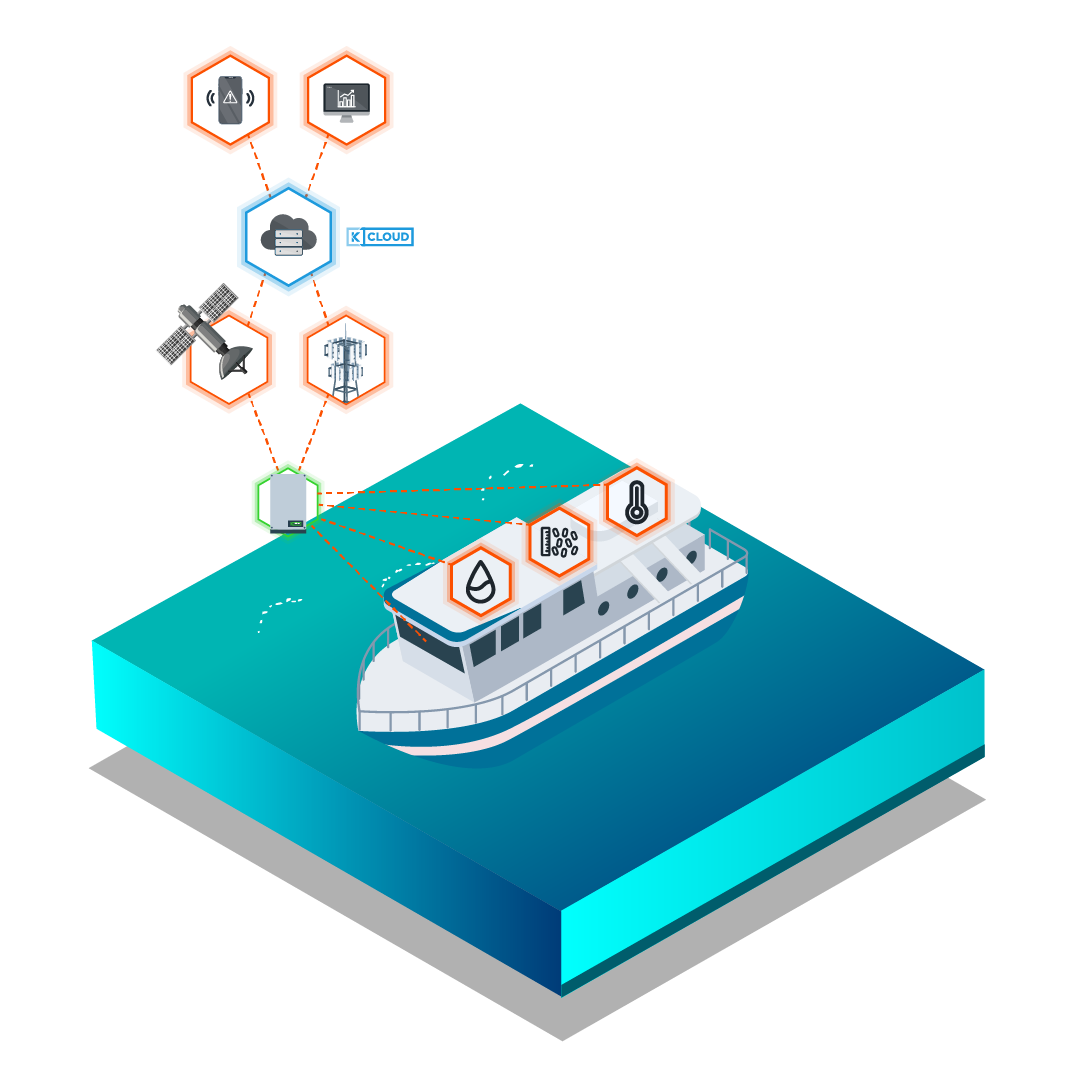

Information is often already measured on these barges, from feed levels to bilge monitoring and even on door and latch openings to detect when one has been compromised. Getting that important data from a remote barge and back to those who need it is still a challenge though – especially given 90% of the planet has no access to terrestrial connectivity service.

Patchy connectivity makes achieving full digitization of the barge difficult and can have other unforeseen consequences. If an issue is not picked up while no one is on the barge, it could be days before it is resolved – meaning feeding may not have gone to plan or a piece of equipment is damaged beyond repair

Integrating all data sources into one, single, easy to use insights platform gives local teams access to information they can act on when issues arise, and keeps central teams updated during periods where no team members are on board.

The benefits of digitization are clear –

- Preventive maintenance, underpinned by historic and current data trends to inform decision-makers when issues may arise, results in cost-savings and a reduction in time on the barge for team members unless necessary

- Continuous monitoring of feed levels minimises waste and can inform operators of the most efficient feed patterns for their fish

- Digital twins can be built using the data gathered continuously, meaning local and central teams have a full overview of barge equipment, fuel and feed levels, and even the surrounding environmental conditions depending on what sensors are deployed.

This is where Krucial Connected Seafarm can help.

Krucial Connected Seafarm is an innovative end-to-end solution that allows operators to remotely monitor sensor data across key barge areas and receive alerts when an issue arises. Using its drop-in hybrid communications system that switches automatically between cellular and multiple satellites depending on availability, operators can get continuous insights into barge conditions, even in offshore and off-grid areas.

The solution is robust, resilient and easy to install – and can digitize a whole barge in a matter of hours, no matter its location. Future development will allow for video monitoring in addition to in situ sensor data being accessible remotely.

Operators can increase their digital ROI quickly and easily with Connected Seafarm, reduce the need for on-site presence and get more insight into their barge performance and condition. Issues can be picked up immediately, while team members can get on with other more beneficial tasks.

Equipment as expensive as feed barges need to be monitored in ordered to maximize their effectiveness. Only with a digitized system can that happen – and that means deploying reliable, resilient connectivity to ensure you make the most of your digital technologies.